An international team of scientists have made a polymer with pores which can be fine-tuned to speedily separate different small molecules - with applications ranging from carbon capture to fuel cells.

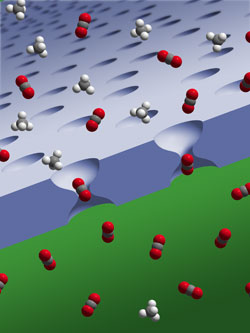

Hourglass-shaped pores give the polymer membrane superior selectivity

© CSIRO, Australia

|

Many current polymers are either not selective enough or don't let molecules pass through quickly -the holes are either too big or too small.Other polymers are extremely rigid and can be difficult to make into membranes.

The new material, made by scientists from Korea, Australia and the US, has 'hourglass' shaped pores that resemble the highly-selective ion channels found in cells. With careful processing, the size of the pores can be changed to allow different molecules to pass through. The polymer can also be dissolved and painted onto a solid surface.

Heating the dissolved polymer to between 300-500°C causes intramolecular rearrangements that makes the structural bonding increasingly tight until it becomes a solid film. By varying the temperature of the reaction and the mix of monomers, the scientists made polymers with different pore sizes.

Selective separation is possible with carbon molecular sieves but they can be difficult to make into membranes. Young Moo Lee, co-author of the paper, told Chemistry World the new material could be used to purify natural gas and for carbon capture, as '[the] polymers exhibit the merits of both existing polymer membranes and carbon molecular sieves'.

The scientists found that doping the polymer with different materials also changed its properties. Adding an acid, for example, boosted the polymer's proton conductivity to beyond that of any existing polymer, the researchers say- opening up applications in fuel cells.

Neil McKeown, a professor of organic materials chemistry at Cardiff University, UK, told Chemistry World: 'What is remarkable about these new materials is the high selectivity they display. They have hit upon a happy compromise between good selectivity and high permeability whilst maintaining ease of processing into practical membranes.'

Jonathan Edwards