Mazda Motor Corporation has unveiled a new generation of catalytic converters that use 70 to 90 per cent less of the precious metals which help to purify exhaust emissions.

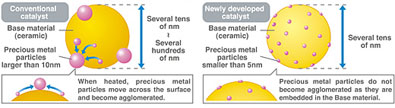

The converters rely on nanoparticles of the catalytic metal, each less than five nanometres across, studded onto the surface of tiny ceramic spheres. The Japanese firm claims this is the first time 'a catalyst material has been achieved that features single, nanosized precious metal particles embedded in fixed positions.'

Automotive catalysts use platinum, rhodium and palladium to speed up chemical reactions of pollutants such as nitrogen oxide, carbon monoxide and hydrocarbons, to create non-toxic emissions.

By using nanoparticles of the precious metals instead of larger particles, less metal is needed to produce the same surface area over the ceramic base of the catalyst.

This simple concept had not been utilized in the past because exhaust heat can make the nanoparticles migrate over the surface of the ceramic bead, agglomerating into larger particles, explained Michael Zins, deputy director of the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden, Germany. This reduces the overall surface area of the metal, cutting the converter's efficiency.

Mazda reckons it has overcome the agglomeration problem by embedding the precious metal nanoparticles into the ceramic in fixed positions - but it's not saying how. 'Mazda is not giving any technological idea how they are doing it.,' Zins told Chemistry World. 'They are only saying, "We have the technology to do it."'

The nanoparticle-studded ceramic sphere could cut the use of platinum-group metals in catalytic converters

© Mazda

|

Jochen Münzinger, Mazda spokesman in Germany, would say only that Mazda has worked on the technology for 4 years. He also declined to discuss commercial details or timelines, saying only: 'We intend to put this new catalyst to practical use in the near future, but we cannot disclose which car adopts this first.'

Major development

Zins described the use of nanoparticles to produce catalysts as a major development, and one that all automakers would like to copy. 'I am sure all other companies are working on the technology,' he said.

Indeed, Mazda's claim comes just two months after rival Japanese automaker Nissan announced it had developed a nanotechnology-based catalyst that would cut its precious metals usage by 50 per cent. Nissan, which will share the technology with French partner Renault, intends to launch a new vehicle using the catalyst in late 2008 or early 2009.

The chief benefit of the technology is cost savings, Zins said. Vehicle manufacturers use a large proportion of the world's annual platinum, rhodium and palladium output, and the development could eventually have a big impact on the prices of these metals.

Less platinum and palladium in catalysts could also translate into health benefits. For example, ongoing research suggests that emissions of platinum-group metals from catalytic converters along US highways might be a root cause of an alarming rise in allergies and asthma.

Ned Stafford